Release Date:Aug 15, 2024 Visit:127 Source:G-Star Pte.Ltd.

Amid the wave of energy transition and green development, Gstar’s solar cell production base has reached a historic milestone. On August 15, Gstar's first high-efficiency solar cell was successfully rolled out, marking the official entry of the cell production base into the mass production phase and further advancing Gstar's vertical integration supply chain in Southeast Asia.

A Benchmark for "Smart Manufacturing" in Thailand

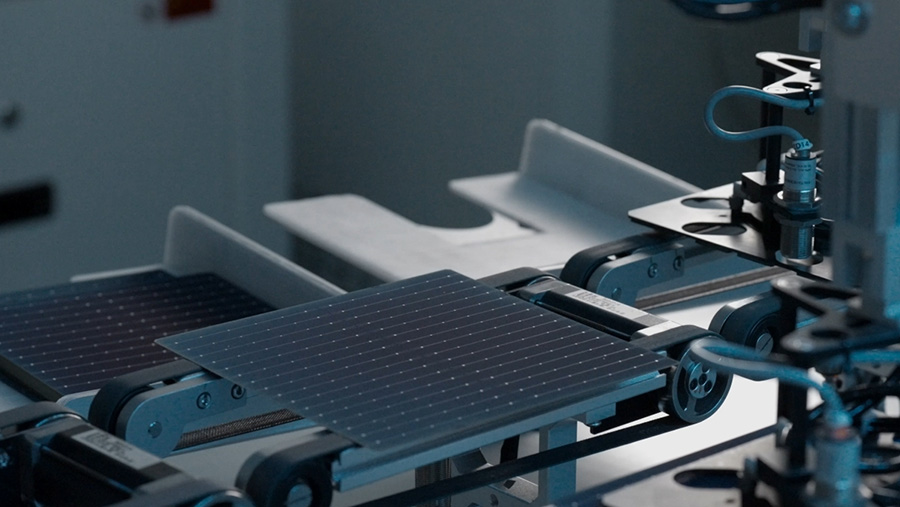

Located in the Rubber Industrial Park in Rayong, Thailand, Gstar’s solar cell production base covers a total area of 120,000 square meters with an investment of 300 million USD. Since the project's launch, we have adhered to the principles of "efficiency, green, and smart" by introducing world-leading automation equipment and intelligent management systems. Our goal is to establish a high-efficiency solar cell R&D and manufacturing base that integrates scale, digitalization, and intelligence, setting a benchmark for "smart manufacturing" in Thailand.

Within just one month, the base has completed critical tasks including equipment installation, commissioning, and the roll out of the first cell. Multiple advanced international automation production lines have been set up, employing industry-leading N-type technology and a comprehensive quality control system, ensuring exceptional quality. With the gradual release of production capacity, the base aims to achieve an annual capacity of 8GW, providing high-quality solar cells for the global market.

Masterpiece in Smart Manufacturing

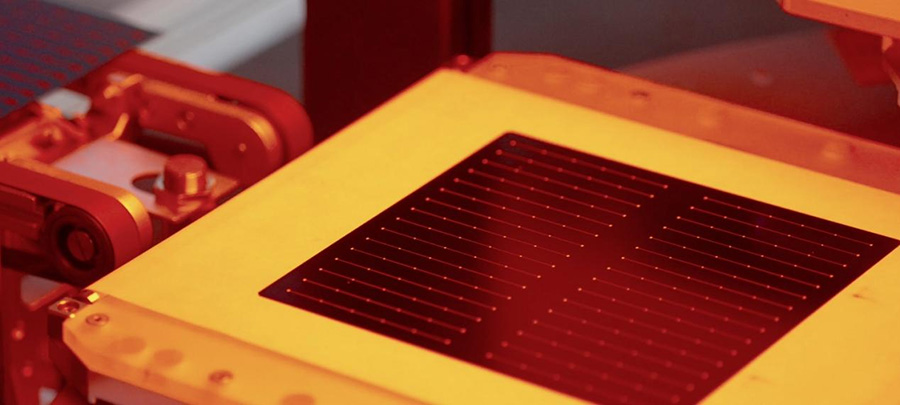

The first cell rolled out in this batch is a masterpiece of Gstar’s solar cell production base. Utilizing N-type high-efficiency cell technology, the cell features a size of 183.75mm and an impressive efficiency of 25.2%. The entire production line achieves a 98% yield rate.

We meticulously control every detail of the production process, from raw material selection and processing to final product inspection, striving for excellence in every step. Through continuous optimization and technological innovation, we aim to enhance the overall performance and stability of our cells, providing high-quality products to the global photovoltaic market.

Global Photovoltaic Supply Chain Solutions Provider

As world economic globalization profoundly drives industrial structure upgrades, Gstar, a leading enterprise in global supply chain solutions, has been closely following the upgrade wave of the photovoltaic industry since its establishment in 2019. It has gradually transitioned from a photovoltaic material trader to an integrated photovoltaic product solutions provider. The business covers a wide range of areas, from photovoltaic material manufacturing to photovoltaic system services, including silicon materials focused on silicon pulling and N-type wafers, metal materials focused on frames and mounting system, and photovoltaic module manufacturing and system services concentrating on N-type and HJT technology. Gstar has established a global strategic layout with its headquarters in Singapore, with branch offices in the United States and Taiwan, China and manufacturing centers in Thailand, Indonesia, and Laos. Our products are exported to North America, Europe, and the Asia-Pacific regions.

Looking ahead, Gstar will continue to focus on optimizing the supply chain, leveraging advanced technology and efficient production to drive widespread application and sustainable development of green energy worldwide.